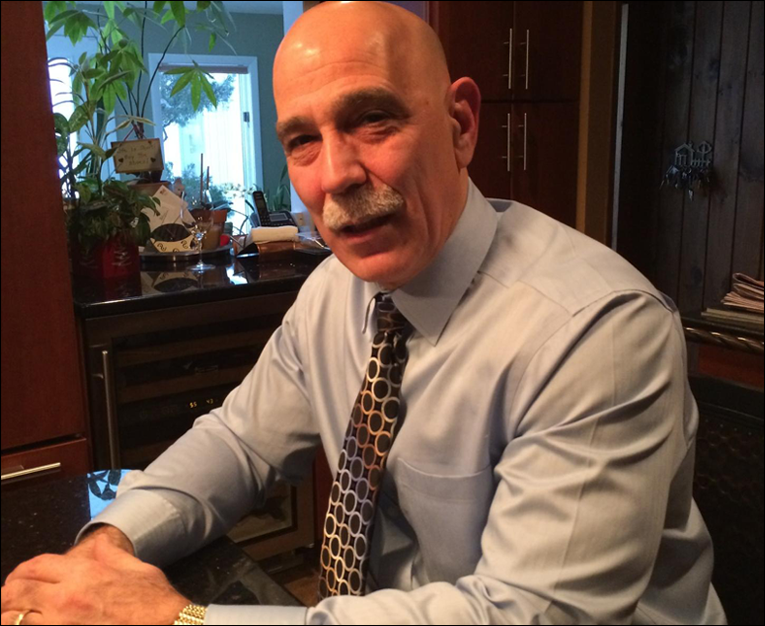

MEET INCOMING AERA CHAIRMAN MARK FELLANTO

Posted on July 26, 2022 by promarengine

We would like to congratulate the President of Promar Engines, Mark Fellanto, on becoming the Chairman of the Engine Builders Association (AERA). This is a great honor as the AERA is one of the most highly regarded associations in our industry. Mark has served on the Board of Directors since 2018 working his way from Director to 2nd Vice Chairman to 1st Vice Chairman and now is the Chairman of the Board.

Please take a look at the great article Engine Professional Magazine wrote about Mark in their most recent issue below.

Owner of Promar Precision Engines in Paterson, New Jersey

BY JIM RICKOFF

Can you give us a little background on your journey into our industry Mark? How did you get started? When did you get started? What influences did you have that helped fuel your interest? Are there family members that work with you?

With the purchase of my first car, in 1974, I found myself frequenting the local parts store so often, that I was offered a job there to bring parts to be machined at the local machine shop. I became friendly with the machinist there, who taught me machining skills while I waited for the jobs to be completed. As a result of my on-the-job education at the machine shop, I convinced my boss at the parts store to invest in head rebuilding equipment. Once he did purchase the machines, a year later, the business took off and he then invested in block and flywheel equipment. After mastering the machining process, I found myself being offered multiple opportunities to work at auto parts stores with machine shop services.

I attribute my success to the local people in the industry, whom I had chosen to model myself after: Raymond Meehan of Jimmy’s Auto Parts and Frank Stanski of Automotive Machine. They truly fueled my fire for this industry.

In 1986, I was offered a position at the Engine Factory, as the head machinist. This company just specialized in engine remanufacturing. Within a few years I was promoted to general manager, where I gained valuable business management knowledge from the owner, Bruce Nelson.

By 1993, I decided it was time to venture out on my own, so I partnered with a brokered engine sales company. We started to build our own engines in a 2500 square foot building. The business took off and within five years, we expanded to a 14,000 square foot facility and employed 72 people.

By 2010, most of my employees were retiring and I considered either selling the business or just retiring myself. The next year’s events changed all that. My daughter became engaged to my now son in law, Kevin Cashin. He joined me in the business in 2011 with no automotive experience. But Kevin is very intelligent and driven and it was easy to recognize his untapped potential. I knew he was the key to the future success of Promar Engines. With that in mind, I invested in new equipment, hired more staff and began to train them in the art of remanufacturing engines. Kevin has surpassed my expectations and he currently runs the day-to-day business operations of Promar. I stay active performing research and development of new engines, purchasing of new equipment and head up training of new staff members. My wife Robin, a retired nurse, helps manage the phones and helps facilitate the core return process. We will see if my 5-year-old grandson, Cole, will follow in his father’s and grandfather’s footsteps and continue on with Promar and complete the third generation of engine builders.

Mark Fellanto begins his one-year term as AERA Chairman of the Board in July.

AERA Chairman Mark Fellanto with his family, pictured left to right: Son-in-law Kevin Cashin, daughter Dina, grandaughter Ella, grandson Cole, Mark and his wife Robin.

Looking at your website, it appears you are well-suited to ship complete engines that you have in stock with FREE freight for both the remanufactured engine and the returned core. Can you expand on how you go to market?

We have several websites and an eBay store since the early 2000s that are maintained by our own IT staff person Brian Baskerville. We ship nationwide which includes FREE domestic shipping, with international shipping costs paid by the customer.

What types of engines or machining do you offer at Promar?

We remanufacture engines and perform machine work on passenger car, light and medium truck (both gas and diesel), classic car, high performance and natural gas generators.

You offer a three year nationwide warranty with your engines; can you explain how that works?

The warranty covers parts and labor for all remanufactured engine on cars and trucks that are one-ton or less.

What types of new technology, equipment have you recently implemented?

We have always tried to invest in the newest machinery in the industry. In the last four years, we have made many purchases of new equipment such as Rottler’s three axis H85AXY cylinder honing machine. We had RMC custom build a block machining CNC center to meet our needs; it can probe, bore, deck and chamfer a block in 20 minutes floor to floor. We also had Rottler design a CNC head machine from their SG10XY head that will do hole-to-hole seat cutting on any cylinder head. Another purchase was Rottler’s S85a resurfacing machine and their VR12 valve grinder. We have a new gas-fired oven being delivered this year from ACE to replace our 15-year-old oven.

Where do you see your shop in 5 years?

Continued growth and advancement with the education of our employees.

How has the COVID Pandemic affected your business?

Yes, in different ways at different times. At first, business slowed down significantly and then, shortly after, picked up significantly. But then we started to face issues with Covid either in illness or symptoms causing employee shortages. Keeping up with the changing protocol on employee regulations for Covid has been a challenge. And starting mid last year, the supply of parts has become our biggest problem due to supply chain issues.

Tell us a little bit about your family, what type of hobbies and interests do you have?

I am happily married to Robin for 32 years. We have one daughter, Dina that we are very proud of. Dina is a grammar school teacher and the mother to our two grandchildren, Cole who is five and Ella who is 18-months-old. My only interests are spending time with my family, working at Promar, or working out at the gym five days per week.

How and why did you decide to become involved in AERA?

I was asked by a friend in the industry, Rick Simko from Elgin Industries, if I would like to serve on the board.

How has AERA helped your business?

The biggest thing is PROSIS online engine specification software and the unmatched technical support.

What goals do you have for AERA with your term as Chairman of the Board?

To help the association continue its path of education. And the advancement of their technical support.

Do you have any advice for other shops in our industry?

We are in an industry that changes rapidly, so be willing to make changes in the engines that you build and continue to educate your employees.